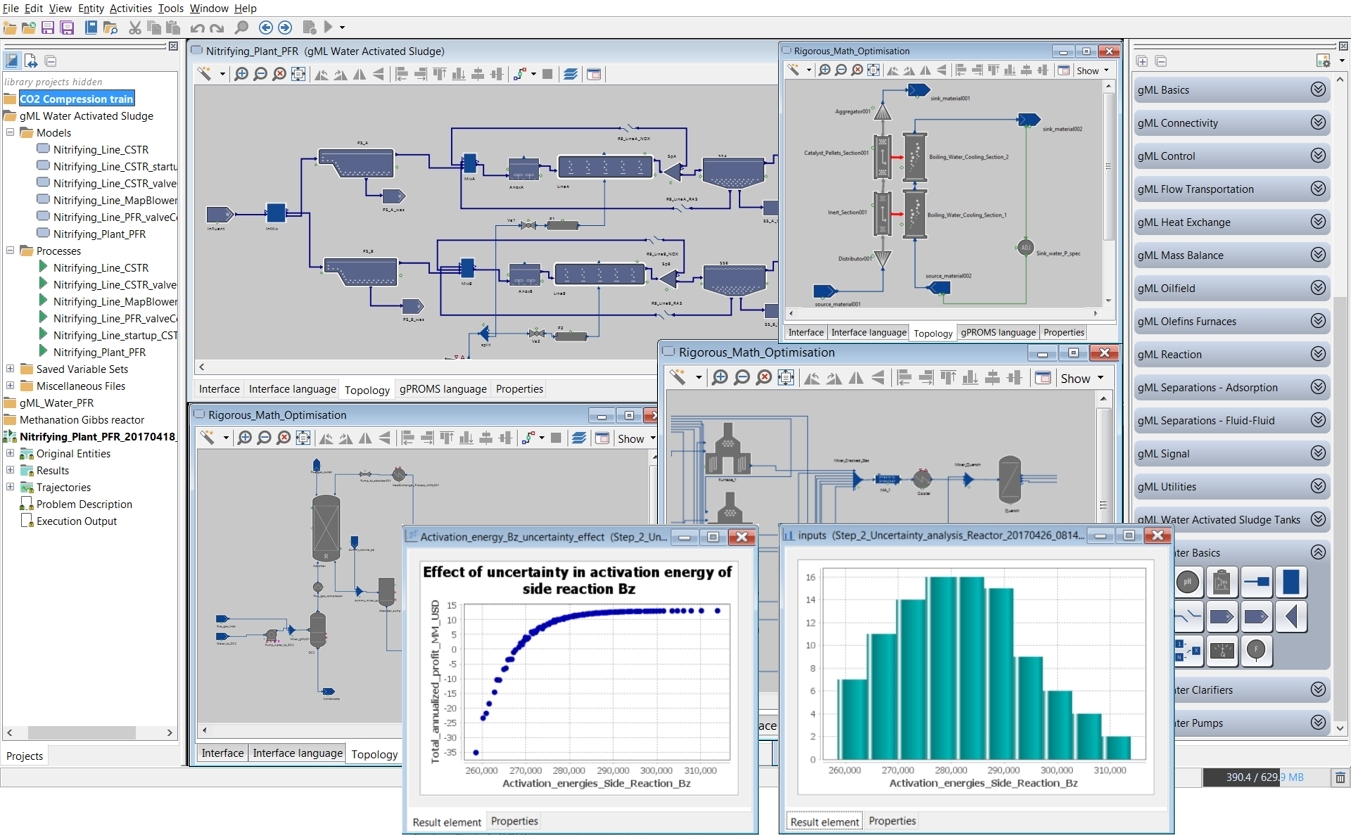

Project environment All elements of a modelling project can easily be accessed and maintained via a project tree structure, within a comprehensive project environment. GSA utilises the power of high-performance computing HPC on multiple cores or cluster machines where necessary. Unique GSA capabilities allow you systematically to explore the process decision space, including performing sensitivity and uncertainty analysis to minimise technology risk. These are just a few:. Extensive capabilities for integrating models with data , by fitting empirical model parameters such as reaction kinetic parameters to laboratory data, or integrating plant data with predictive models to create digital process twins.

| Uploader: | Vudonris |

| Date Added: | 22 February 2017 |

| File Size: | 26.69 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 62699 |

| Price: | Free* [*Free Regsitration Required] |

A detailed predictive model of a polymerisation process, for instance, can run to millions of equations, all of which need to be solved zoftware for every step of the process — within minutes rather than days. This software is widely recognized as a 'best-in-class' simulation package.

How-to Videos

This not only has the potential to shorten the design period significantly, it creates capital and operational savings which will be realised over the lifetime of the sofware. Operation, which usually involves heat-sensitive foodstuffs or pharmaceutical materials, must stay within a very softwade envelope to avoid spoiling the product or creating dry zones. These values, typically termed model parameters, usually have to be determined from real-world eoftware laboratory experiments or pilot plant or operating data as part of a process known as model validation.

These are the companies who will be able to softwaee most rapidly to changing markets in the future. Process Systems Enterprise Ltd. The key element of this is the way it combines first-principle mathematical representation in the form of equations describing the underlying softtware and chemical phenomena of a process with actual observed laboratory or plant data.

Most simulation efforts these days are directed toward supply chain management, rather than toward optimizing designs. They can then be used like any other library model. They are specially designed to handle the simultaneous solution of the large number of equations often hundreds of thousands and sometimes millions that can result from a first-principles modelling approach. Now it is possible to apply this to generate value and create competitive advantage in a number of ways:.

Optimise operation to minimise energy, feedstock use, etc.

PSE: Products - gPROMS - Home

Because gPROMS has an equation-oriented — as opposed to sequential modular — architecture it has many advantages over existing simulation and modelling software.

The gPROMS environment naturally supports both steady-state and dynamic simulation within the same environment, using the same underlying models. Alternatively you can switch to a palette view to access libraries of model icons when building a flowsheet. Home About us The magazine Sponsors Contact us. Estimates of parameter uncertainty are also provided for identifying poor data or for use in risk analysis.

Several of the academic institutions in the UK have been the fountainhead of much of the work in process modeling and simulation. Once you have constructed a gPROMS model, the gPROMS platform allows you to perform many different activities — steady-state and dynamic simulation, steady-state and dynamic optimisation, parameter estimation, state estimation — using the pgroms underlying model.

Get the latest industry news, insights, and analysis delivered to your inbox.

"gProms"—Process Simulation In 3D

Models can be combined with other custom or library models within a process flowsheet. Unlike the usual statistically-based approach, model-based experiment design siftware full advantage of information that is already available, in the form of the mathematical model, to design experiments that can yield the maximum possible information about the system being studied.

This leads to a more efficient operation, closer to the optimum, helping to increase revenues and reduce costs. Unique GSA capabilities allow you systematically to explore the process decision space, including performing sensitivity and uncertainty analysis to minimise technology risk.

Take the area of heat and mass transfer as an example. Company Profile Email Us. I agree to the Terms and Privacy Statement. Skip to main content.

Submit an article or letter. Continue to use the site as normal if you're spftware with this or find out more about cookies. This ability to solve gigantic mathematical problems quickly and robustly was a key element of our original research at Imperial College London that led to the creation of gPROMS. Easy custom modelling with no need to program numerical solution methods Lumped and distributed parameter spatial, size distribution, etc.

"gProms"—Process Simulation In 3D

How I got here. This enables critical design and operational decisions to be based on rigorous quantitative analysis. Process modelling power At the heart of softwarw platform is its ability to represent to a high level of fidelity using first-principles models.

No comments:

Post a Comment